Dr. Boris Muravin

As long as I remember myself, Acoustic Emission was an important part of my life. Both of my parents were among the first scientists that researched Acoustic Emission in the former Soviet Union. When I born in 1974, my Father, Prof. Gregory Muravin has finished already his PhD thesis and published several articles dedicated to dynamic fracture mechanics of metals in collaboration with my mother Dr. Ludmila Lezvinsky and under supervision of Prof. Victor Finkel. In this research, they studied stress distribution around propagating cracks and different related physical phenomena such as emission of stress waves (AE) and temperature changes. Since late 1960s and until 2016 when Father passed away, my parents worked and researched Acoustic Emission together.

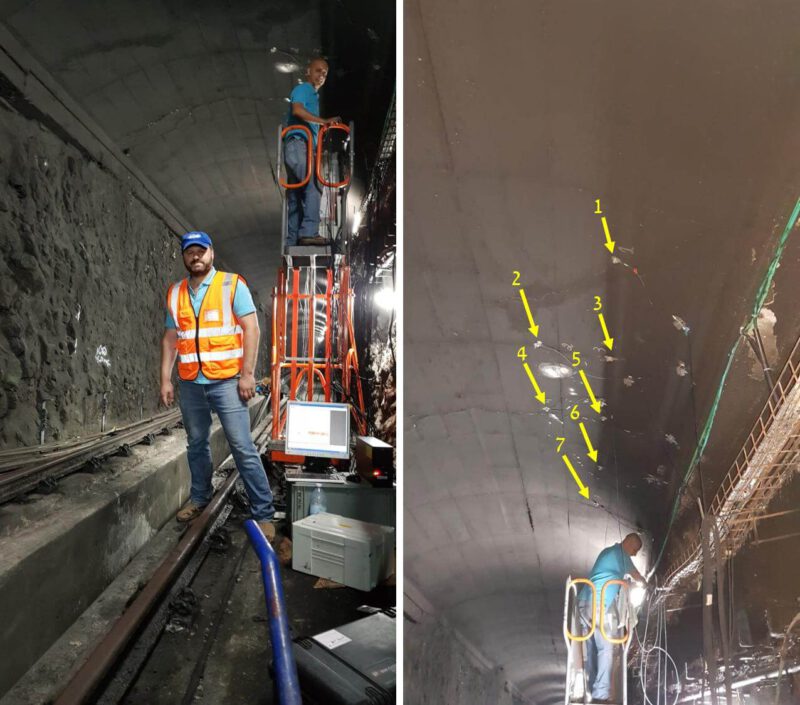

From early childhood, I remember almost-daily discussions at home about different tests and experiments that my parents did. I was around 5 years old when my Father took me with him to a project in Russia’s far East near Baikal lake where he inspected a new tunnel. Since then, almost every summer during school holidays I was traveling with my parents to tests sites or just was spending a good time in the laboratory for non-destructive testing that my Father was managing in the Moscow Research Institute of Transport Construction.

In 1992 our family repatriated to Israel and my parents resumed their work on Acoustic Emission but for a small private company. Later, in April 1994 they co-founded MPD company in Israel. Few months later I join them too for 18 amazing years of my life. My Father was my teacher and mentor. He was guiding me step by step during all my studies from the first degree to PhD. He grew me as a man and as a specialist. We were doing together hundreds of projects worldwide. These were inspections of bridges, chemical and nuclear reactors, hundreds of steam lines in Europe, USA and many other countries. With a time, I adsorbed my parents’ approach for development of new acoustic emission applications which was proven in so many cases. Acoustic emission is a material related phenomenon which directly depends on material properties, applied stresses (operational conditions), failure mechanisms and other factors. Only comprehensive research of all factors can provide a good basis for correct application of acoustic emission technology and interpretation of acoustic emission results. This was a reason why we spent so big efforts on material testing, metallography, numerical simulations, software development, literature review and publications. Unfortunately, in 2011 me and my parents left the company, but this is a different story. End of this chapter was a new beginning in our professional life.

In parallel with my work in MPD, in 2003 I finished PhD thesis in Tel Aviv University dedicated to dynamic fracture mechanics of multiple cracks. My supervisers were Prof. Eli Turkel and my Father. In my hart I understand that success of my studies depended very much on fanatical support and love of my Father.

In 2011 my Mother founded Integrity Diagnostics Ltd. that I joined later in 2012. Since then, I am CEO and owner of this company. In the beginning, I had no many resources to hire engineers and purchase equipment. There were many concerns if I will able to generate new projects and develop new AE applications. It was difficult time, but Father was sure somehow in my success and supported in all ways he could. My parents were consulting me until 2016 when Father passed away and Mother could not emotionally continue. Today I am proud to lead Integrity Diagnostics Ltd., take a part in fascinating new projects, train new generation of engineers in acoustic emission and fracture mechanics, develop new AE standards. I am confident in success and development of Acoustic Emission as one of the main sensing technologies in non-destructive testing, structural health monitoring, IOT, machine and process monitoring. In memory of my Father, I decided to spend more time and efforts in popularization of Acoustic Emission and this website is a part of this effort.