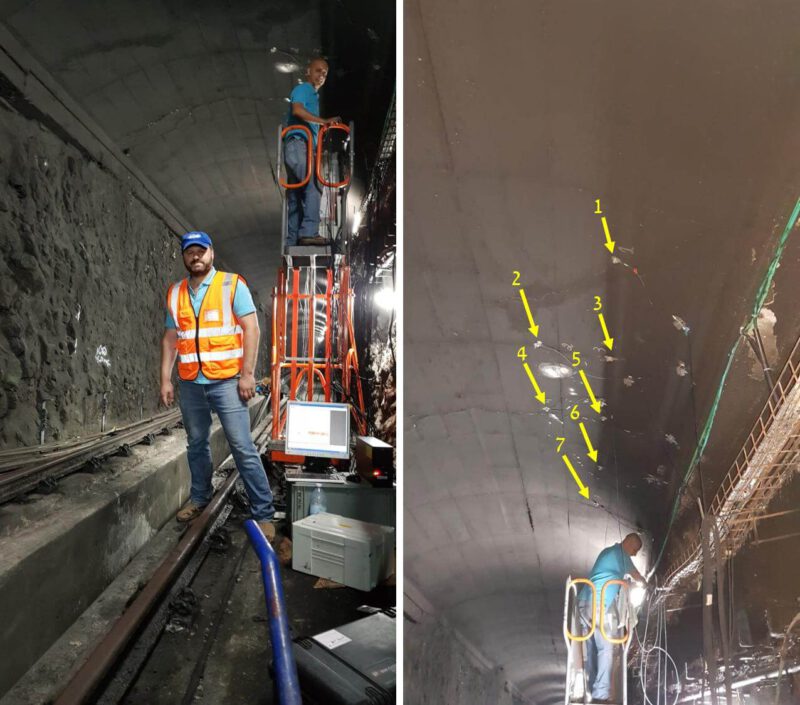

#AcousticEmission examination of #steam piping in operation is one of the most complex #AE applications that requires high level of expertise and sophisticated analysis. This is because steam flow, friction, mechanical knocks at hangers and turbine produce a huge fluctuating ultrasonic noise that has to be filtered out while detecting signals related to defects development. However, advantages of AE testing of high energy piping are significant. AE allows early detection of cracking, creep and other flaws in welds in operating lines without expensive shutdowns, removal of insulation or building scaffolds.

#AE #highenergypiping #steam #steampiping #creep #SHM #structuralhealthmonitoring #ndt